Industrial

Studies, Compliance & Documentation

System gap analysis to ISO 55000

CMMS/EAM reviews

Equipment availability, productivity and OEE

Risk-based inspections (API 580)

Seismic assessments

Corrosion assessments

Energy efficiency studies

New plant design reviews

AACE cost estimating

HAZOP/HAZID studies handling

ISO 50001 readiness review

Audits energy management information systems (EMIS)

Plant-wide energy audits (electricity and natural gas)

Pre-feasibility and feasibility studies

Hydrogen risk assessment & safety analysis

Pulp &

Paper

Chips, sawdust, hog, chemicals

Groundwood, kraft and sulphite cycles

Digester area

Refining, TMP, CTMP, BCTMP

Brownstock washing and stock prep

Bleach plant and hi-density storage

Black liquor handling, concentration

Steam plant, recovery and power boilers

Green/white liquor handling and recausticizing

Steam cycles, recovery, use and reduction

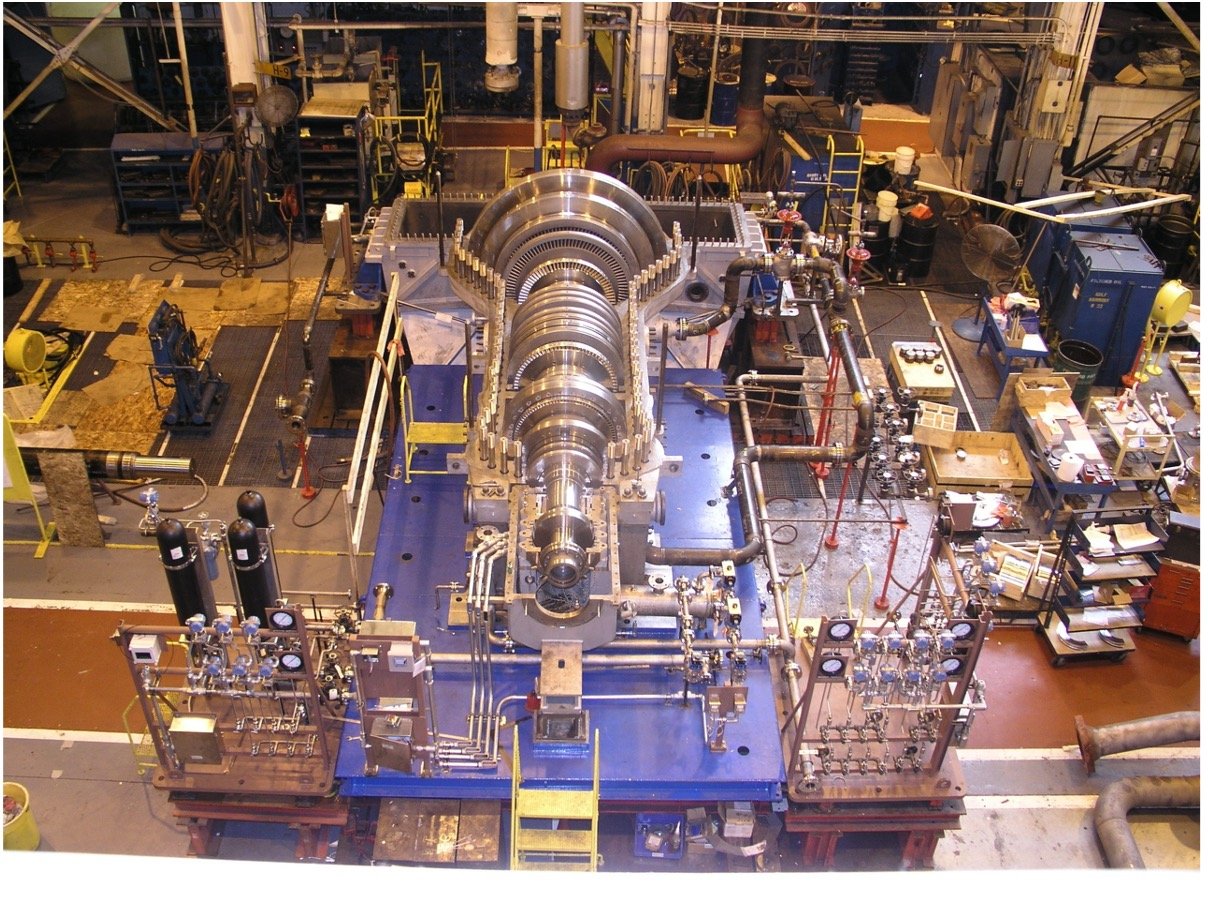

Power generation and turbines

Pulp/paper machine

Dust control

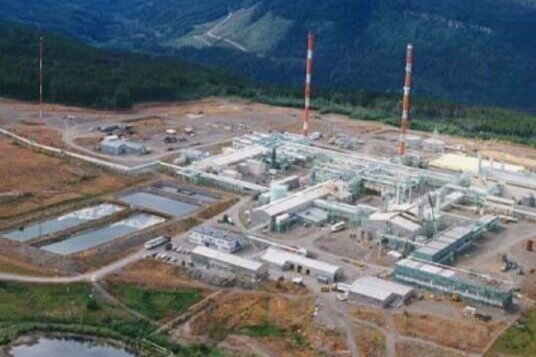

Northern

Remote Sites

Sacré-Davey is equipped to design and operate in arctic environments for the following services:

Project management

Process engineering

Mechanical engineering

Energy management

Civil engineering

Structural engineering

Electrical engineering

To read more about our services, click the link below:

Food &

Beverage

Capacity studies and debottlenecking

Plant utility studies & evaluations

Product and raw material storage

Bulk materials handling systems

Process & layout modeling

Process optimization

Boilers, heating and refrigeration systems

Warehouse design & planning

Waste water collection & treatment

Dust collection systems

Plant commissioning/decommissioning

Energy management

H&S and food safety improvements

Past Projects

This project included the conversion of the existing dough mixers refrigeration system from a “Direct expansion” system to a “Glycol” system, and a complete overhaul of the 2500 Lb. bread dough mixers. The Project achieved all defined objectives and resolved the environmental issues associated with the old system.

This project involved decommissioning of the manufacturing plant and distribution center, and building repairs and modifications. The project achieved all defined objectives, and was completed under budget.

This project involved integrating new feed conveyors and a new palletizer into an existing bottling line. This project involved the design of new motor control panels, PLC IO panels, PLC IO panels, generation of electrical layouts, cable tray and grounding plans, cable lists, and a bill of materials for installation. Construction Management and Commissioning service were also provided by SDE.

Okanagan Spring Brewery undertook replacement of older fire tubed boilers with state of the art steam generators. The new system allowed for increased steam capacity and efficiencies whilst maintaining boiler branch staffing requirements. Sacré-Davey Engineering was retained for providing vendor and general contractor Request for Proposal documents, assessment of bids, and Construction Management.

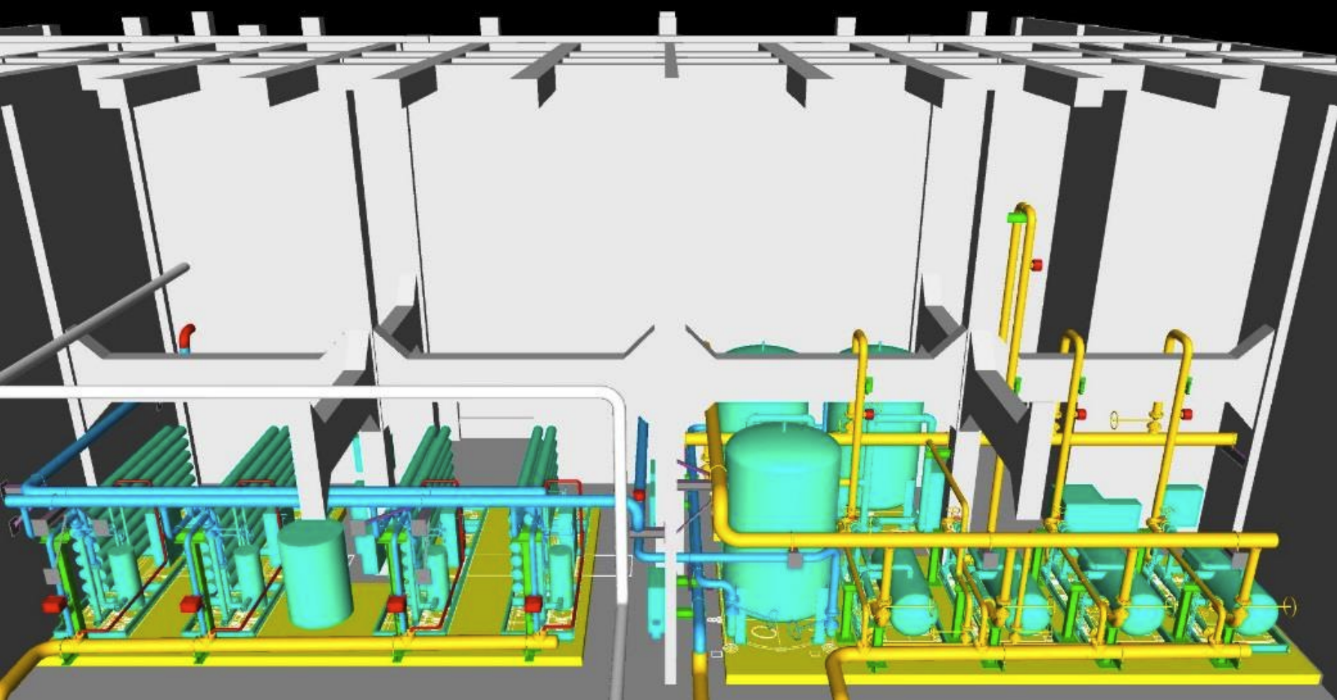

Our pulp and paper client identified an opportunity to optimize steam resources and increase revenue by installing a 65 MW condensing steam turbine/generator set. Mill-wide steam consumption was reviewed and maximum efficiency gained by converting several turbine drives to electric; optimizing steam generating boilers; and installing the turbine generator & associated equipment.

Port Townsend Paper had an in-situ separate train demineralizer water system feeding three separate boilers. Sacre-Davey’s primary scope of work was integration of these units within the mill and detailed design for ancillary system requirements.

SDE completed an integrity assessment on steam, condensate, chloride, brine, and slurry piping systems within the process plant.

SDE provided design review, stress analysis and design input for a 1000 PSIG, 20” diameter pipeline servicing the new Kwoen Gas Plant in Northern BC.

Sacre-Davey Engineering conducted NDT, visual inspections, a pump performance assessment and an investigation of the equipment’s historical and operational information.

SDE was contracted to prepare a study and capital cost estimate for a water treatment system that would capture and recover the boiler water treatment system and blow down waste as boiler feed water to eliminate liquid discharge.

Project involved the enlargement of an existing 77,000 sq. ft. operation- al commercial bakery by 11,000 sq. ft. through the creation of new GMP ‘white box’ production area and additional packaging space. This re- quired the up-grading of existing ingredient handling areas and ambient and forced cooling rooms, as well as adding a complete new production line. The existing mechanical and electrical fit-out was also enhanced to suit.

This project includes the detailed design for the No. 2 paper machine fourdrinier table rebuild at Port Townsend Paper. Sacré-Davey staff reviewed the documentation provided by the technology provider, IBS, and integrated the system requirements within the mill. We provided a scope of work construction package that described and detailed the multidisciplinary work and specific requirements for contractor installation.