Ore Sorting

Remove waste early, increase valuable material output.

What is Ore Sorting?

A technology that uses advanced sensors and algorithms to separate valuable rocks from waste rocks in real time. Applying ore sorting technology increases the average ore quality and reduces the quantity of low-value rocks entering the mill.

This results in reduced milling costs, less tailings generation and lower water consumption. The rejection of low-value rocks increases feed grade and allows for higher metal production rates.

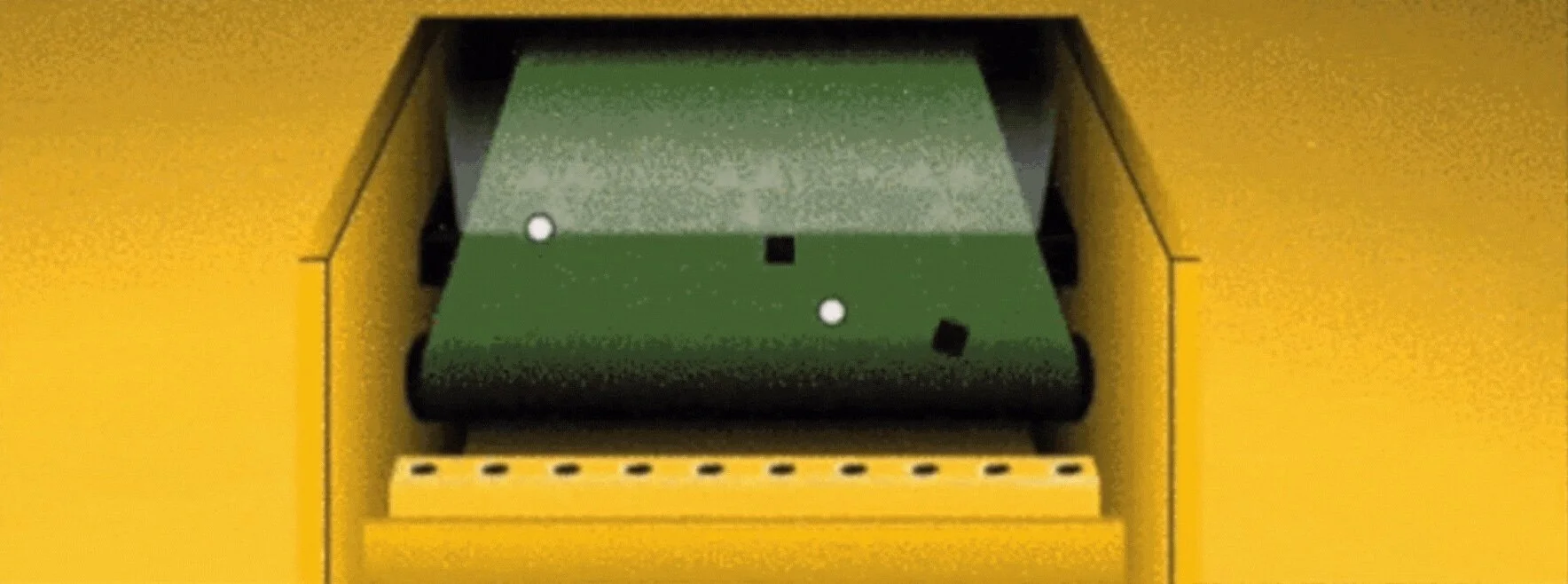

Pilot Sorter

In collaboration with the University of British Columbia, Sacré-Davey designed and constructed a pilot ore sorting lab. This facility enables Sacré-Davey to assess the viability of ore sorting using bulk samples and to refine processes to enhance accuracy, speed, and effectiveness in ore sorting.

Types of Sensor Based Ore Sorters

-

Particle Sorting

Particle sorters employ either a single or multiple sensors to scan a single layer of rocks on a conveyor or chute, measuring various qualities of each individual rock. The machine utilizes a set of algorithms to compare the rock details with a predetermined criterion for good ore. Rocks that do not meet the criteria are separated into a waste pile, while the good ore proceeds for processing.

-

Bulk Sorting

Bulk sorters, measuring the grade of mass quantities of ore simultaneously, utilize sensors that can be mounted on a shovel or a bulk conveyor. Equipped with a mechanical arm for sorting by redirecting flow, bulk sorters efficiently handle rocks at or near the mine face. Integration with the mine dispatch system enhances fleet management efficiency, optimizing the sorting process.

Particle Sorters

The particle ore sorter can be seamlessly integrated into a new development or retroactively added between the excavation and processing stages. This minimizes the volume of material entering the mill and decreases ore dilution. Consequently, this leads to lower operating costs in milling processes and mine tailing storage.

Bulk Sorters

Bulk sorters play a crucial role in recovering valuable ore from waste zones and eliminating waste rock from ore zones. The implementation of the sorter, whether before the primary crusher or after, depends on the chosen method of bulk ore sorting.

Download the ore sorting guide.

Discover the key insights, strategies, and technologies that can revolutionize your mining operations. Our comprehensive Ore Sorting Guide is your go-to resource for maximizing mill feed grade, minimizing waste rock processing, and optimizing overall efficiency in your mining processes.