SACRÉ-DAVEY

EXCELLENCE IN PROJECT DELIVERY

-

Mining & Mineral Processing

Providing bespoke solutions that optimize processes, enhance value, and de-risk projects.

-

Energy

Helping conventional and renewable energy companies integrate advanced technologies, develop critical infrastructure, and deliver greater performance.

-

Industrial

Supporting clients with scaling up technology, sustaining capital projects, and Greenfield developments through excellence in engineering and project delivery.

Community

Serving our communities since 1986.

Trust

r

We do what we say.

Delivery

Results, the first time.

IN THE NEWS

Celebrating the Career of René Mandeville

After an extraordinary career spanning over 40 years in the industrial gas and hydrogen sectors, René Mandeville is embarking on a new chapter in life into a well-earned retirement.

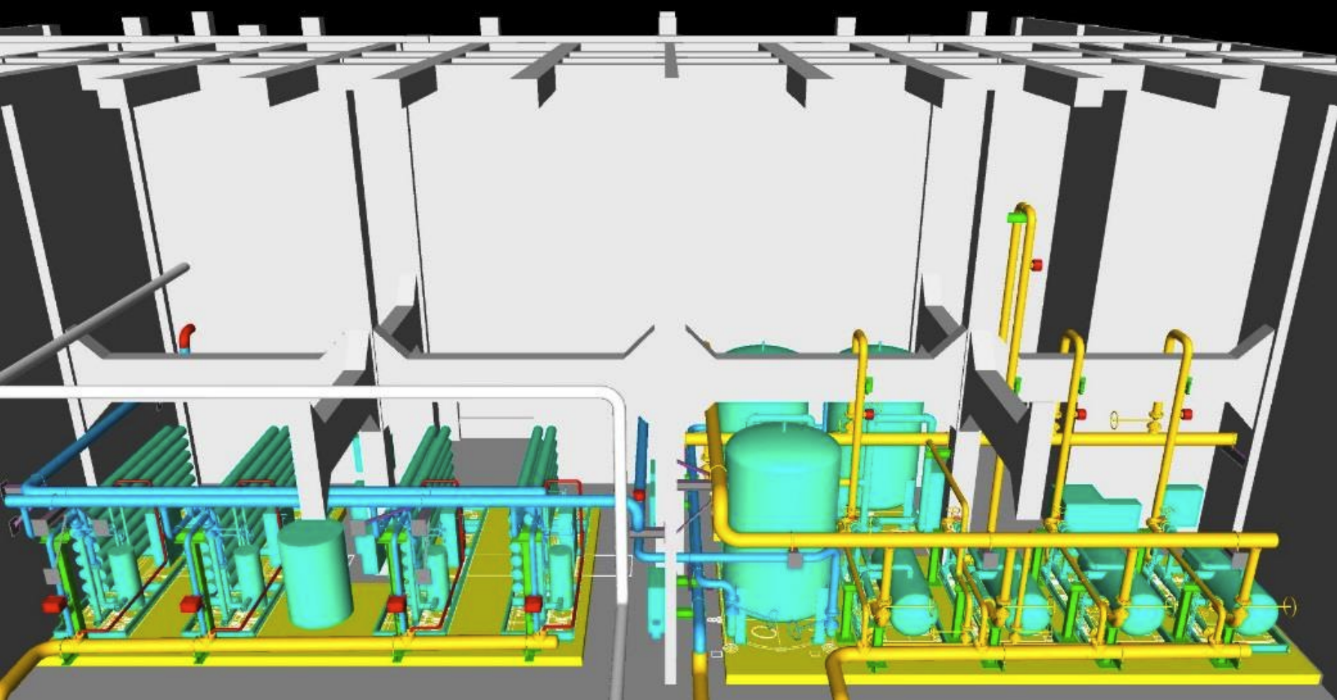

Atura Power selected St. Catharines, Ont. based CEM Engineering and Sacré-Davey Engineering of North Vancouver, B.C. (CEM/Sacre-Davey joint venture) to advance the engineering of Atura Power’s first green 20-megawatt (MW) hydrogen production facility - the Niagara Hydrogen Centre.

Sacré-Davey Engineering was involved with conducting an updated feasibility study for Sabina Gold & Silver Corp.’s Goose Project.

Sacré-Davey Engineering was chosen as Hydro-Québec’s hydrogen expert for the world’s first and largest green hydrogen production facility. The water electrolysis plant will be built in Varennes, Quebec, and is to produce 11,100 metric tons of green hydrogen annually. Both the hydrogen and the oxygen, a by-product of the electrolysis process, will be used in a biofuel plant to produce biofuels from residual waste for the transportation sector. For the full story, click below.

Sacré-Davey Engineering was featured in the December 2020 issue of Innovation Magazine. In this article, Sacré-Davey VP, Warren Johnson, discusses the future of hydrogen energy as a low carbon energy source, the benefits of low carbon fuels, and the changes that need to happen. To read the full article, click the button below.

Sabina Gold and Silver Corp.’s has announced Sacré-Davey Engineering’s role as Detailed Engineer for the Goose Mine processing plant at the Back River Project in Nunavut.

SAMPLE PROJECTS

SDE performed a study to remove the existing 350 HP pebble crushing units and replace with larger 900 HP units. In addition, a dust collection system would be installed.

SDE worked to produce a comprehensive scoping study for the optimization and development of a new mine. SDE’s responsibilities included all onsite facilities including the mill building (from the Crusher to the Concentrate Load-out), offices, maintenance shops, stores, camp, water & wastewater treatment, and transportation of tailings.

This project was for a large open pit Zn mine located in an extremely cold weather environment in the USA. Sacré-Davey Engineering was tasked with identifying suitable sorting techniques, carrying out the option evaluation and performing detailed engineering of the sorting plant.

This project included the conversion of the existing dough mixers refrigeration system from a “Direct expansion” system to a “Glycol” system, and a complete overhaul of the 2500 Lb. bread dough mixers. The Project achieved all defined objectives and resolved the environmental issues associated with the old system.

This project involved decommissioning of the manufacturing plant and distribution center, and building repairs and modifications. The project achieved all defined objectives, and was completed under budget.

This project involved integrating new feed conveyors and a new palletizer into an existing bottling line. This project involved the design of new motor control panels, PLC IO panels, PLC IO panels, generation of electrical layouts, cable tray and grounding plans, cable lists, and a bill of materials for installation. Construction Management and Commissioning service were also provided by SDE.

Okanagan Spring Brewery undertook replacement of older fire tubed boilers with state of the art steam generators. The new system allowed for increased steam capacity and efficiencies whilst maintaining boiler branch staffing requirements. Sacré-Davey Engineering was retained for providing vendor and general contractor Request for Proposal documents, assessment of bids, and Construction Management.

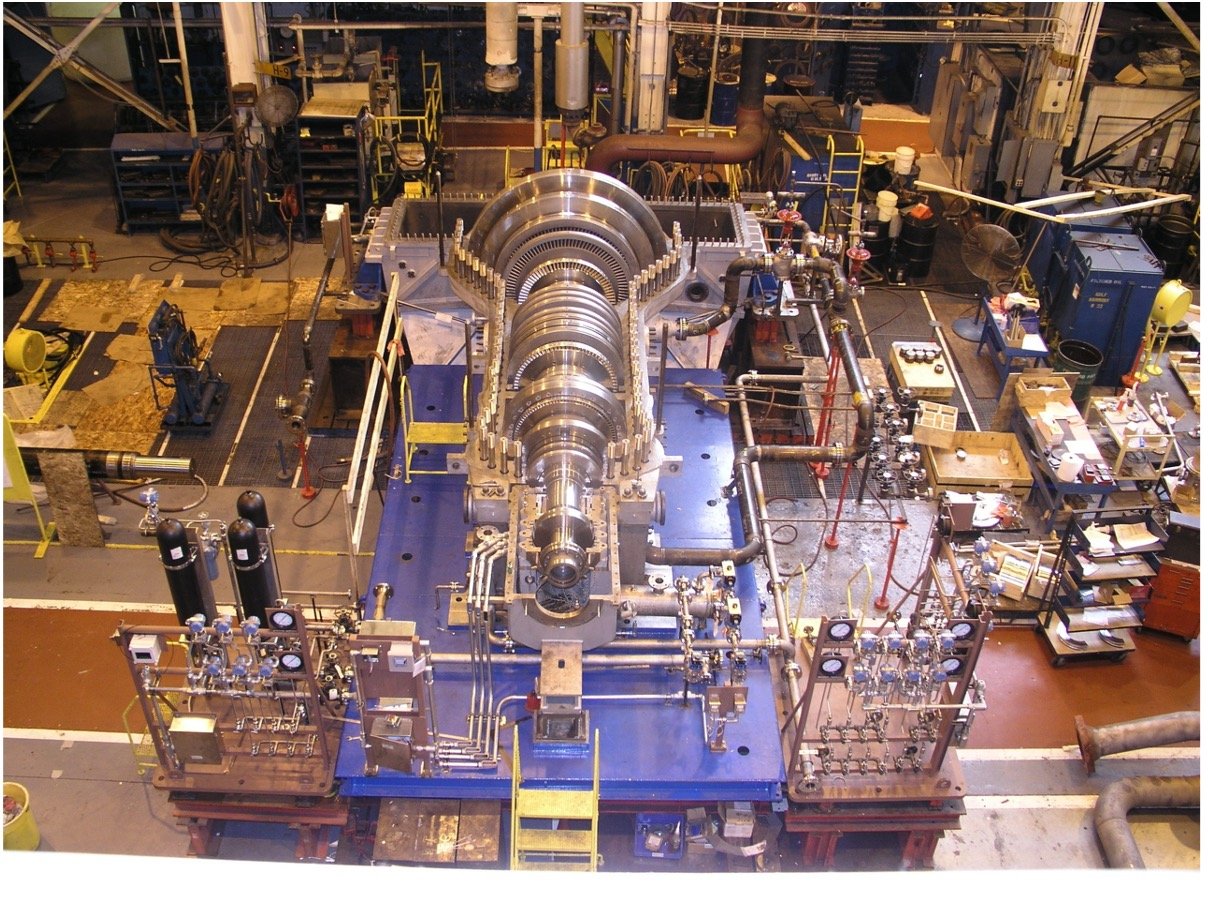

Our pulp and paper client identified an opportunity to optimize steam resources and increase revenue by installing a 65 MW condensing steam turbine/generator set. Mill-wide steam consumption was reviewed and maximum efficiency gained by converting several turbine drives to electric; optimizing steam generating boilers; and installing the turbine generator & associated equipment.

Port Townsend Paper had an in-situ separate train demineralizer water system feeding three separate boilers. Sacre-Davey’s primary scope of work was integration of these units within the mill and detailed design for ancillary system requirements.

Sacre ́-Davey Engineering now offers energy efficiency studies at zero cost or risk to the customer using Fortis BC’s updated incentive program.