Biodiesel Plant Detailed Design

SDE performed a feasibility study to integrate General Biodiesel’s equipment and processes into their existing plant, producing up to 10 million gallons/year of biodiesel.

Bio-Crude Technology Development

SDE was responsible for scale-up, design, and process optimization of a supercritical HTL technology from pilot plant to commercial demonstration scale.

Bio-Glycol Technology Development

This project incorporated the technology development, scale-up, and design of laboratory, bench, pilot and commercial-scale equipment. The process includes conditioning of residues and separation of contaminants to produce clean feedstock sugar streams, catalytic hydrotreating of sugars to produce bio-glycols and polyols, and separation of pure products via crystallization and distillation.

Biodiesel Plant Design

Sacré-Davey was involved with the Development of a 17.5 million gallon/year biodiesel plant utilizing local used cooking oil, yellow grease, and beef tallow as feedstock. SDE was responsible for the complete process design, detailed design, construction management, commissioning, start-up and warranty for the plant.

Biodiesel Handling Facility

Our client wanted to install a facility to offload biodiesel, store it, then reclaim and blend it into traditional diesel in a blending range from B5 to B20. Sacré-Davey provided complete multi-disciplinary engineering for the detailed design of this project.

Biodiesel Design/Start-Up

SDE used their experience with solid metal catalysts in renewable fuels to design a pretreatment process for a broader range of feedstocks (40% FFA max) to suit Benefuel’s high-temperature and high-pressure catalytic technology.

Feedstock Preparation

SDE developed a glycerol esterification technology from small pilot scale to a full-scale commercial process capable of converting 6 million gallons per year of fatty material to biodiesel feedstock.

Project Portfolio .

Project Portfolio .

From groundbreaking engineering solutions in renewable energy to optimizing complex industrial processes, SD’s portfolio showcases a commitment to excellence and a greener future.

Client

Varennes Carbon Recycling

Year

Present

Project

Green Hydrogen Facility

Sector

Energy

In the development of an 87-megawatt electrolyzer plant generating 11,100 tons per year of green hydrogen and oxygen for supply to Énerkem's biofuel production facility, Accelera by Cummins was chosen as the PEM electrolyzer. Sacré-Davey, leveraging its extensive history in the hydrogen market, was engaged to deliver Owner’s Engineering Services. This encompassed electrolyzer selection, integration, and guidance on balance of plant design for the facility. Following the Phase 1 contract completion, a performance appraisal rated Sacré-Davey's services as "Exceptional," achieving a commendable 95% rating.

Client

ReGen III

Year

2022

Project

Decarbonization & Renewable Oil Refinery

Sector

Energy

Sacré-Davey received the FEED (Front-End Engineering Design) contract for a 5600BPD re-refinery. The project integrates established refining technologies into a proprietary process, enabling the extraction of higher quality base lubricating oils compared to conventional re-refineries. Positioned to meet the growing demand for efficient used motor oil re-refining and aligning with the emphasis on reducing carbon dioxide equivalent emissions, this facility represents a significant step in resource conservation. Sacré-Davey successfully delivered the front-end engineering scope within a best-in-class schedule, meeting the requirements of both investors and clients.

Client

Agnico Eagle | Pinos Altos Mine

Year

2019

Project

Ore Sorting Evaluation & Demonstration Plant

Sector

Mining & Minerals

Sacré-Davey took charge of conducting testing and assessing diverse technologies, utilizing samples sourced from different mines. The goal was to identify the technology that could deliver the most significant overall impact on the project's economics. Subsequently, Sacré-Davey offered integration engineering services for the construction of a demonstration plant at Agnico Eagle’s Pinos Altos mine. The plan included the installation of two additional plants by 2020.

Client

Confidential

Year

2023

Project

Green Fuel Feasibility Study

Sector

Energy

A European-based client, operating in shipping, energy, technology, and real estate, is exploring Canada as a prospective location for their green fuels plant. The feasibility assessment undertaken had several objectives: 1) Evaluate the availability of appropriate biomass sources, 2) Examine potential plant sites, 3) Offer an economic analysis to substantiate investment decisions, 4) Identify counterparties and potential partners, and 5) Assess the regulatory landscape.

Client

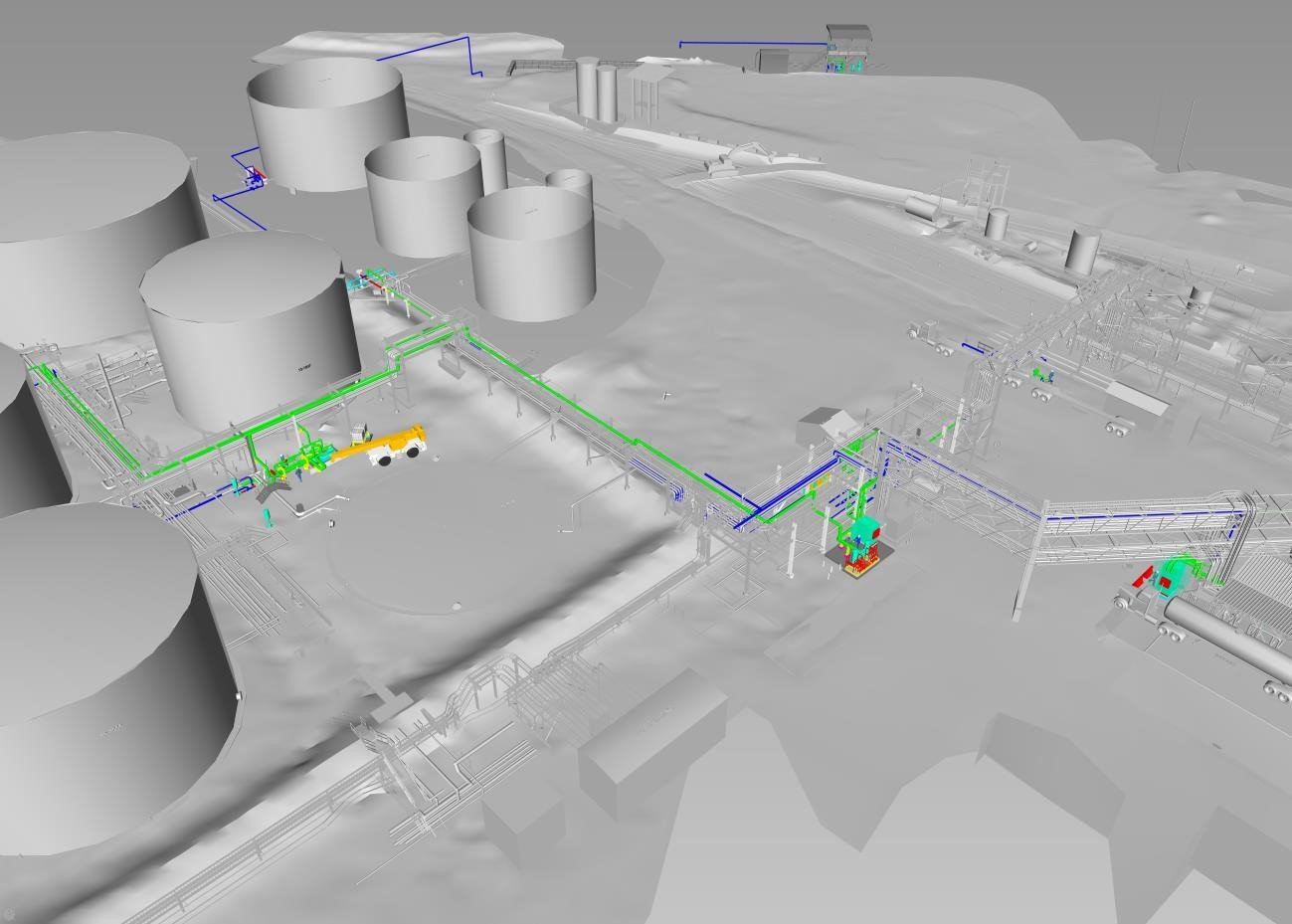

Pembina, Vancouver Wharves

Year

2020

Project

Diesel Tank EPC & detailed CapEx estimate

Sector

Ports & Marine

In the Procurement and Construction phases of the North Vancouver Terminal diesel tank project, Sacré-Davey undertook the construction of two diesel fuel tanks, with nominal capacities of 80,000 and 120,000 barrels respectively. The project involved a meticulous review and development of the Engineering, Procurement, and Construction (EPC) project schedule, along with a detailed Capital Expenditure (CapEx) estimate following AACE principles.

Client

The University of British Columbia

Year

2022

Project

Decarbonization & Energy Infrastructure

Sector

Energy

Sacré-Davey successfully executed multiple energy infrastructure projects for UBC, encompassing the development of their (1) bioenergy plant, (2) expansion of the biomass hot water plant, and (3) enhancement of the steam distribution plant. These energy infrastructure initiatives spanned a university campus, strategically aimed at enhancing operational efficiency and energy performance within buildings of various ages.

Client

Plains Midstream Energy Company

Project

Oil & Gas Cogeneration Study

Sector

Energy

Sacré-Davey conducted a cogeneration scoping study for on-site electric generation at Natural Gas Liquids extraction plants. With an annual electricity cost exceeding $10 million, the challenge was unevenly balanced electric and steam demands, fluctuating capacities, and regulatory restrictions. Sacré-Davey proposed an innovative solution optimizing electricity and steam production for the complex, achieving an estimated 20% Internal Rate of Return (IRR), surpassing the client's requirements.

Client

Tech Highland Valley Copper

Year

Present

Project

Plant Wide Audit

Sector

Mining & Minerals

Conducting a comprehensive plant-wide infrastructure audit, Sacré-Davey aims to identify risks associated with the existing infrastructure and collaborate with the client in formulating an action plan to mitigate these risks. The ultimate objective is to ensure the reliable operation of the infrastructure throughout the remaining lifespan of the mine. Currently, Sacré-Davey is actively engaged in a site-wide mechanical and structural infrastructure audit encompassing existing equipment, piping, storage tanks, grating, and structural buildings as part of routine maintenance activities.

Client

Harnois Énergies

Year

2020

Project

First Public Hydrogen Fueling Station

Sector

Energy

Sacré-Davey undertook the site integration engineering for the inaugural public hydrogen vehicle fueling station in the Province of Québec. This pioneering project incorporated on-site green hydrogen generation utilizing AWE technology, compression, and storage, seamlessly integrated with two hydrogen fuel dispensers in Québec City. The system facilitates a commercial, green hydrogen facility, covering production through the tailpipe, catering to up to 40 cars daily.

Excellence in Project Delivery