Reverse Osmosis Demineralization Replacement

Project Description

Port Townsend Paper grappled with an outdated and unreliable in-situ separate train demineralizer water system serving three boilers. Due to the system's aging nature, unreliability, and the exorbitant costs associated with repairs and maintenance, a decision was made to opt for a complete system replacement. A technology provider was chosen to implement a single-pass system with the capacity to handle flows ranging from 500 to 800 gallons per minute (gpm).

Project Scope

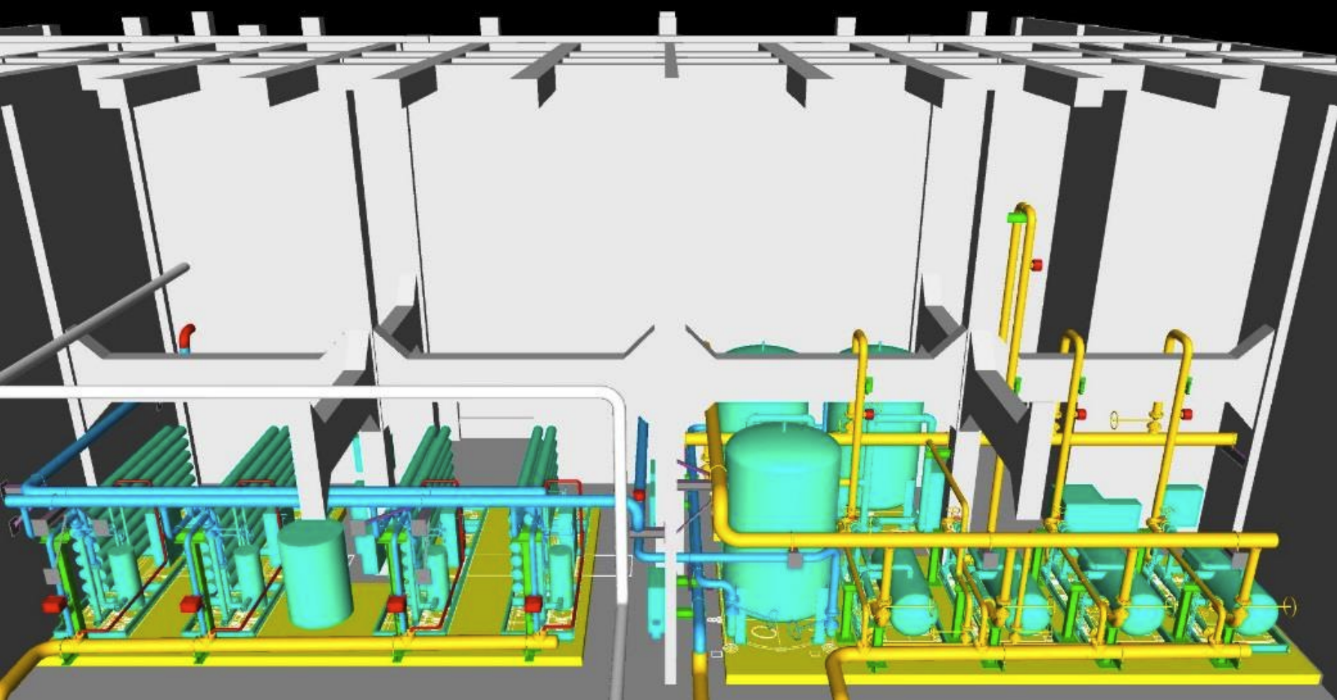

Sacré-Davey efficiently managed the IFC (Issued for Construction) package, covering system demolition and equipment skid installation for demineralization. Their multidisciplinary expertise, including process, mechanical/piping, structural, electrical, and instrumentation/controls, was showcased. The solution included a strategic 3D model for efficient project execution and optimized room spacing by relocating smaller equipment. Overcoming structural challenges in a century-old floor, Sacré-Davey used helical piles and structural foam. Leveraging prior hot switchover experience, tie-in activities were meticulously scheduled, ensuring a seamless operational transition with detailed procedures.