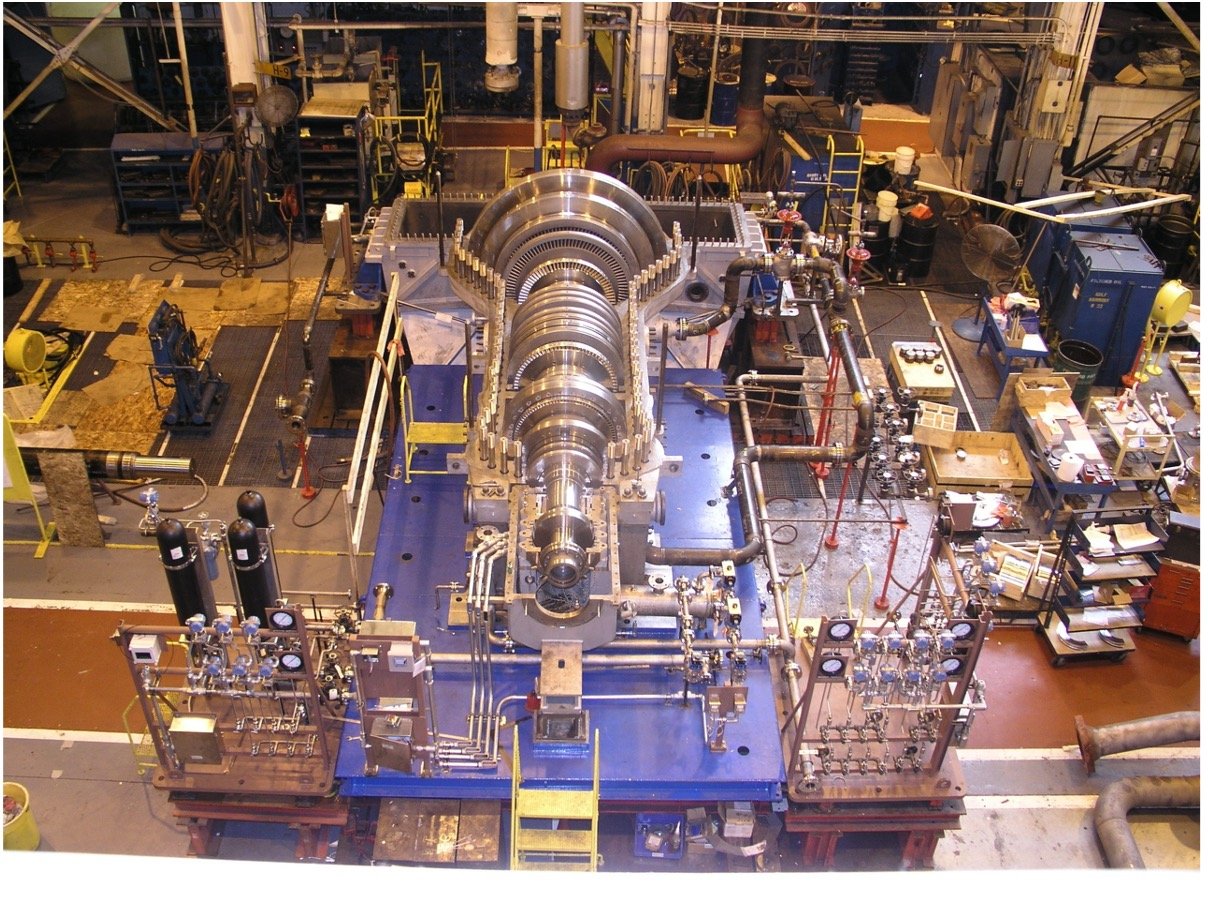

65 MW Cogeneration Turbine

Project Description:

The pulp and paper client, recognizing an opportunity to optimize steam resources and boost revenue, engaged in the installation of a 65 MW condensing steam turbine/generator set. A comprehensive review of mill-wide steam consumption led to increased efficiency through the conversion of several turbine drives to electric, optimization of steam-generating boilers, and the installation of the turbine generator along with associated equipment. The project encompasses the turbine, a new condenser, mill-wide steam piping, cooling towers, electrical switchgear, controls, and includes engineering and implementation assistance.

Project Scope:

Sacre-Davey partnered with Binnington Development Corporation to deliver definition-level engineering services, developing a preliminary process design and cost estimate for the project. The collaborative effort involved the purchase and installation of a TG set and ancillary equipment, process control systems, grid interconnection, protection, major switchgear, and substation. The project was executed on an EPCM basis, encompassing equipment specification and procurement, detailed process mechanical, electrical instrumentation, and controls engineering, with continuous project and construction management support.