Studies, Compliance & Documentation

System gap analysis to ISO 55000

CMMS/EAM reviews

Equipment availability, productivity and OEE

Risk-based inspections (API 580)

Seismic assessments

Corrosion assessments

Energy efficiency studies

New plant design reviews

AACE cost estimating

HAZOP/HAZID studies handling

ISO 50001 readiness review

Audits energy management information systems (EMIS)

Plant-wide energy audits (electricity and natural gas)

Pre-feasibility and feasibility studies

Hydrogen risk assessment & safety analysis

Pulp &

Paper

Chips, sawdust, hog, chemicals

Groundwood, kraft and sulphite cycles

Digester area

Refining, TMP, CTMP, BCTMP

Brownstock washing and stock prep

Bleach plant and hi-density storage

Black liquor handling, concentration

Steam plant, recovery and power boilers

Green/white liquor handling and recausticizing

Steam cycles, recovery, use and reduction

Power generation and turbines

Pulp/paper machine

Dust control

Northern

Remote Sites

Sacré-Davey Engineering is equipped to design and operate in arctic environments for the following services:

Project management

Process engineering

Mechanical engineering

Energy management

Civil engineering

Structural engineering

Electrical engineering

To read more about our services, click the link below:

Food &

Beverage

Capacity studies and debottlenecking

Plant utility studies & evaluations

Product and raw material storage

Bulk materials handling systems

Process & layout modeling

Process optimization

Boilers, heating and refrigeration systems

Warehouse design & planning

Waste water collection & treatment

Dust collection systems

Plant commissioning/decommissioning

Energy management

H&S and food safety improvements

Past Projects

Studies, Compliance & Documentation

Zero Liquid

Discharge

Reclaim Barge Conditional Assessment

Design Review of Natural Gas Pipeline

Piping Integrity

Assessment

Pulp & Paper

No. 2 Paper Machine Fourdrinier Table Rebuild

RO Demineralization

Replacement

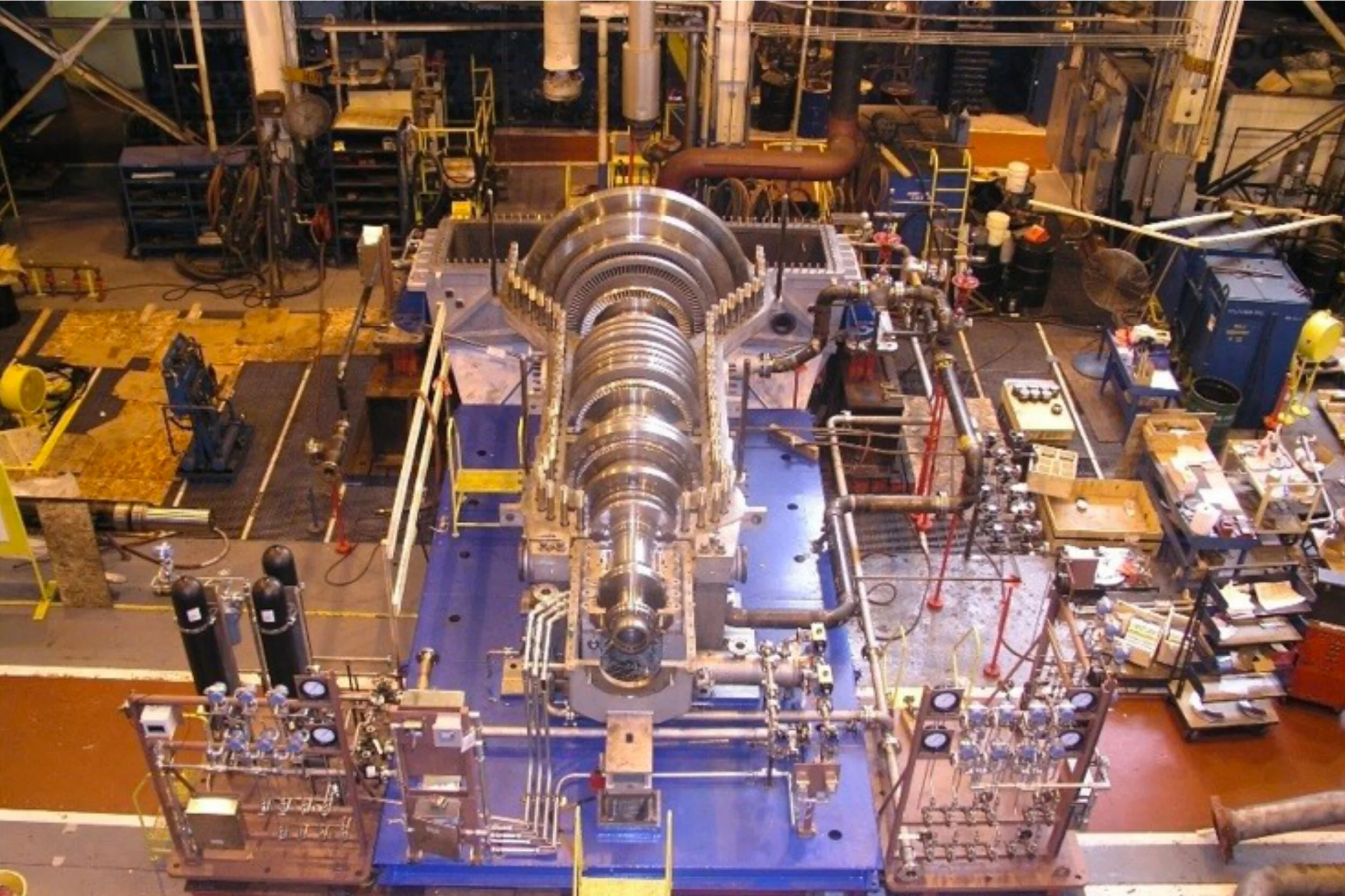

65MW Cogen

Turbine

Northern Remote Sites

Igloolik Bulk Fuel Depot Upgrade

Building Foundations in Continuous Permafrost

PCSP

Resolute

Iqaluit

Airport

Food & Beverage

Steam Supply

Upgrade

Conveyer

Line

Bakery

Decommission

Dough Mixer Refrigeration System Glycol